Give us a call or provide your contact details below, and a Dentsply Sirona representative will be in touch soon.

Solving complex engineering and chemistry challenges requires balancing several factors simultaneously. The same is true for the components of a 3D printed denture. In the rapidly growing printed denture segment, some manufacturers focus on one material property only or cite data that’s clinically irrelevant.

Experienced dental lab technicians understand that a balance of engineering factors leads to high performance dentures.

Denture Base

The role of a denture base is to provide support for denture teeth, as well as serving as an optimal interface between these and the alveolar bone and gingival tissues. A balance between high impact resistance (defined by Fracture Toughness) and Flexural Strength/Modulus addresses the concerns of patient comfort and denture breakage from dropping or chewing.

- Flexural Strength or Modulus too high will result in a rigidity, which can be uncomfortable to the patient.

- Rigidity can cause imbalance towards fracture in the midline when chewing or dropping.

- A denture base with a good balance will be both durable and comfortable.

Denture Teeth

Denture teeth require a balance of factors to achieve Wear Resistance, the critical mechanical factor for chewing surfaces.

- High wear resistance maintains desired aesthetics and the integrity of occlusal surfaces for efficient chewing.

- If material toughness is too high, then material wear resistance declines.

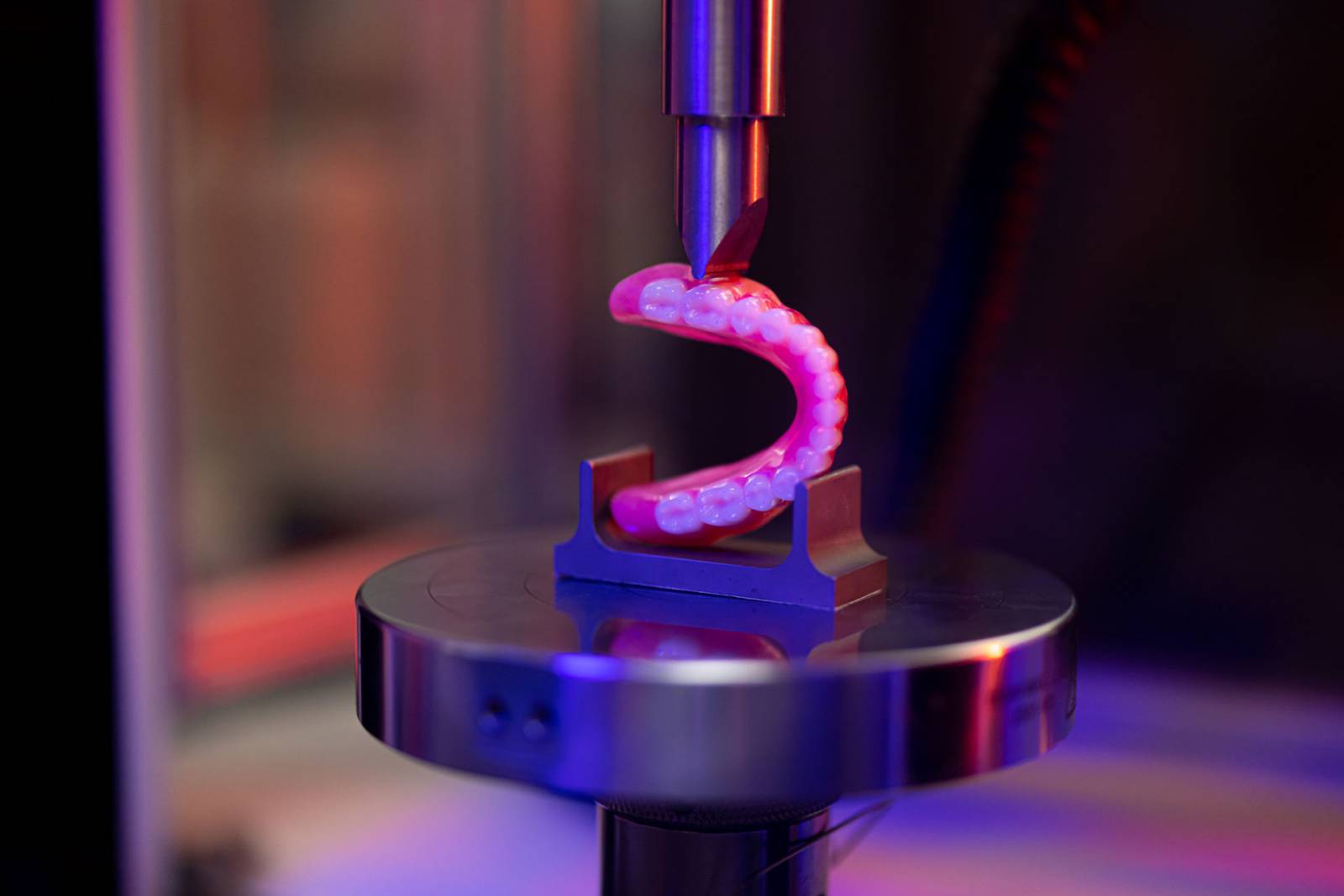

Expanding the possibilities

Dentsply Sirona leverages over 100 years of denture design and test experience to innovate, test, and validate the optimal balance for its materials.

It is important for Dental Laboratories to have confidence in the expertise behind the materials they use, and the critical balance achieved in these materials, created by teams of scientists and clinical experts, to meet the changing workflows of modern digital dental laboratories.

Dentsply Sirona is pleased to share a small sampling of the extensive testing that leads to the optimal balance for denture bases and denture teeth.

High Impact Denture Base

A high impact denture base material can resist the stresses of chewing and the rigors of everyday patient handling without fracturing. Lucitone Digital Print™ 3D Denture Base meets both criteria of a “high impact” denture base.1

- Work of Fracture of 3047 J/m2 at 37⁰C

- Fracture Toughness of 2.5 MPa/m1/2

Furthermore, it is rigid enough to hold the teeth effectively in position while chewing, and strong enough to provide stability from mastication and irregular resorption of the alveolar ridge.

Lucitone Digital Print has an average of 0.02% residual methacrylate content, an amount much lower than the maximum specification requirement of 2.2%3.

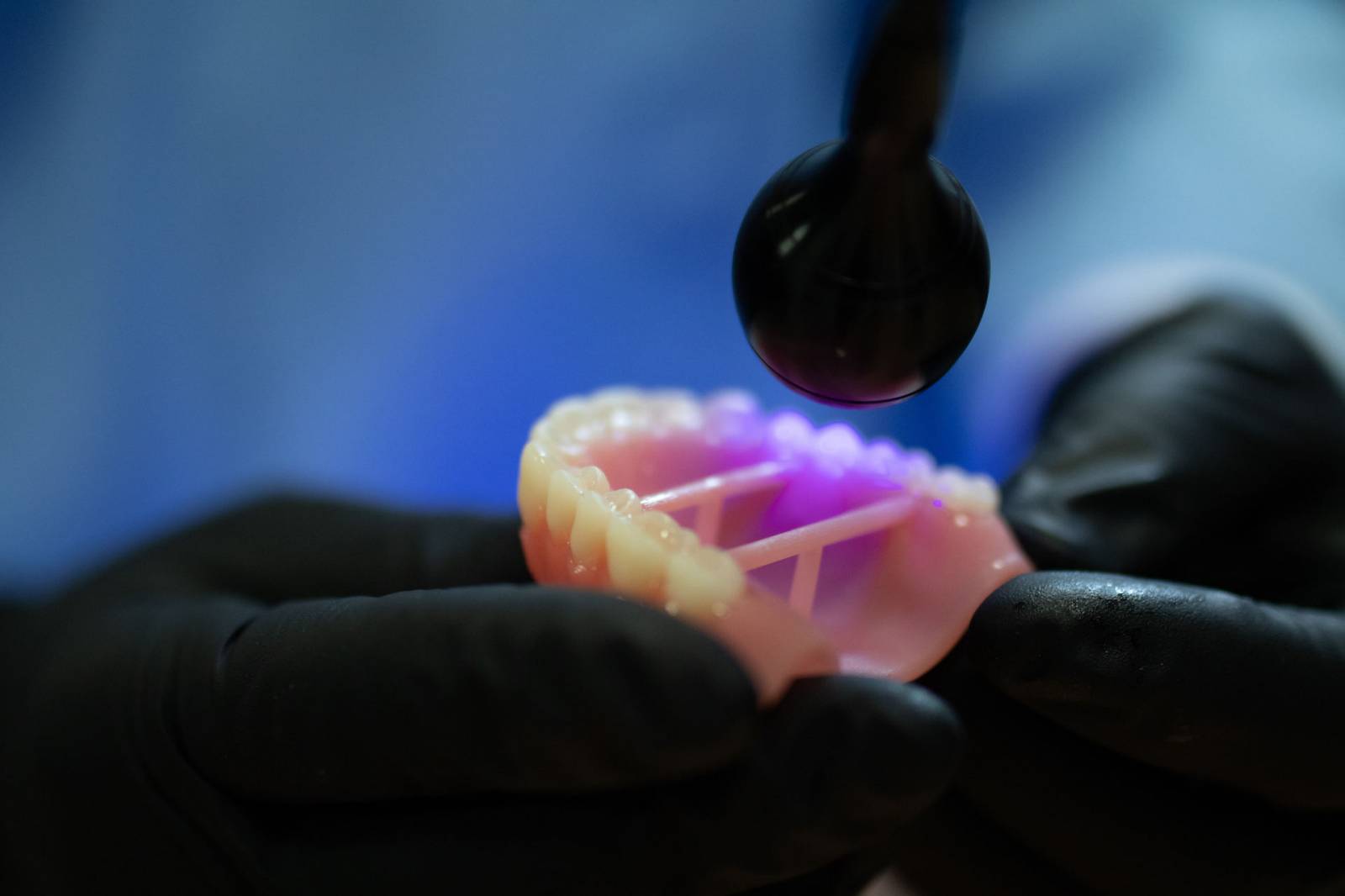

Digital Denture Teeth

Progressive wear of occlusal surfaces of denture teeth results in insufficient tooth support, causing functional and esthetic impairments, thus reducing the longevity of the denture.

Denture Base & Teeth Measurements

Dimensional Accuracy

Lucitone Digital Print™ 3D Denture Base and Lucitone Digital IPN accurately reproduce the dimensions of the computer-assisted design with impressive dimensional accuracy measurements:

- Lucitone Digital Print™ 3D Denture Base: (90% of the printed denture base intaglio surface within ± 0.13 mm the design),7 ensuring optimal fit, function and comfort for the patient.

- Lucitone Digital IPN™ 3D Premium Tooth: (95% of the printed denture base intaglio surface within ± 0.13 mm the design)8, ensuring optimal occlusion, function, and esthetics.

Color Stability

The dental lab seeks reassurance that the color of the denture base will not lighten nor darken away from the shade prescribed by the dentist, while the patient wants confidence that their denture will maintain the color and smile they prefer. Just as with the denture base, or maybe even more important, denture teeth must also show color stability.

- Lucitone Digital Print™ 3D Denture Base stands out in this regard as well, showing no perceptible color change.9

- Lucitone Digital IPN shows no perceptible color change10

Finally, Lucitone Digital Print™ 3D Denture Base and Lucitone Digital IPN Printed Denture Teeth work seamlessly together to address a major cause for concern of patients, dentists, and lab technicians: denture teeth debonding.

- According to industry standards, a bond is considered acceptable if the mode of fracture is cohesive within the tooth or the denture base polymer.

- With Lucitone Digital Print Denture base and Lucitone Digital Fuse Step 2 and Step 3 Total, all cohesive fractures were with the denture base.11

- ISO 20795-1, Section 5.2.10: Maximum Stress Intensity Factor for materials with improved impact resistance ISO “High Impact” is defined as: Total Fracture Work (Work of Fracture) ≥ 900 J/m2 and Maximum Stress Intensity Factor (Fracture Toughness) ≥ 1.9 MPa/m1/2.

- ISO 20795-1:2013: Flexural strength ≥ 65 Mpa, Flexural Modulus ≥ 2000 MPa.

- ISO 20795-1:2013: Less than 2.2% residual methyl methacrylate monomer.

- Dentsply Sirona internal 3-Body wear testing at 37°C, 400,000 cycles.

- ISO 10477:2020, Section 5.4. Flexural strength ≥ 50 MPa.

- ISO 604/ASTM D695.

- Dentsply Sirona protocol for dimensional accuracy of a printed denture.

- Dentsply Sirona protocol for dimensional accuracy of a printed denture teeth.

- ISO 20795-1:2013 Section 5.2.5: Material shall show no more than a slight change in color.

- ISO 22112:2017 Section 5.3.3: Material shall show no more than a slight change in color.

- ISO 20795-1: The bond shall be considered to be acceptable if the mode of fracture is cohesive within the tooth or the denture base polymer.

Internal data on file. For more information, contact Consumables-Data-Requests@dentsplysirona.com