inLab MC X5 – efficient and flexible

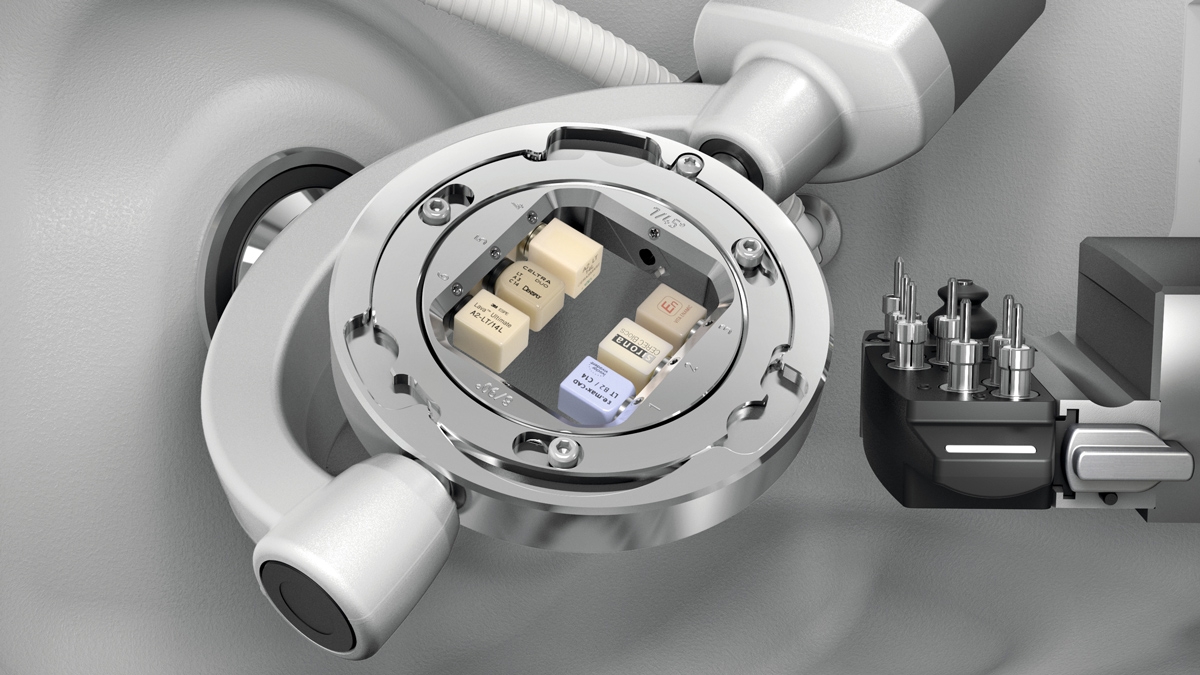

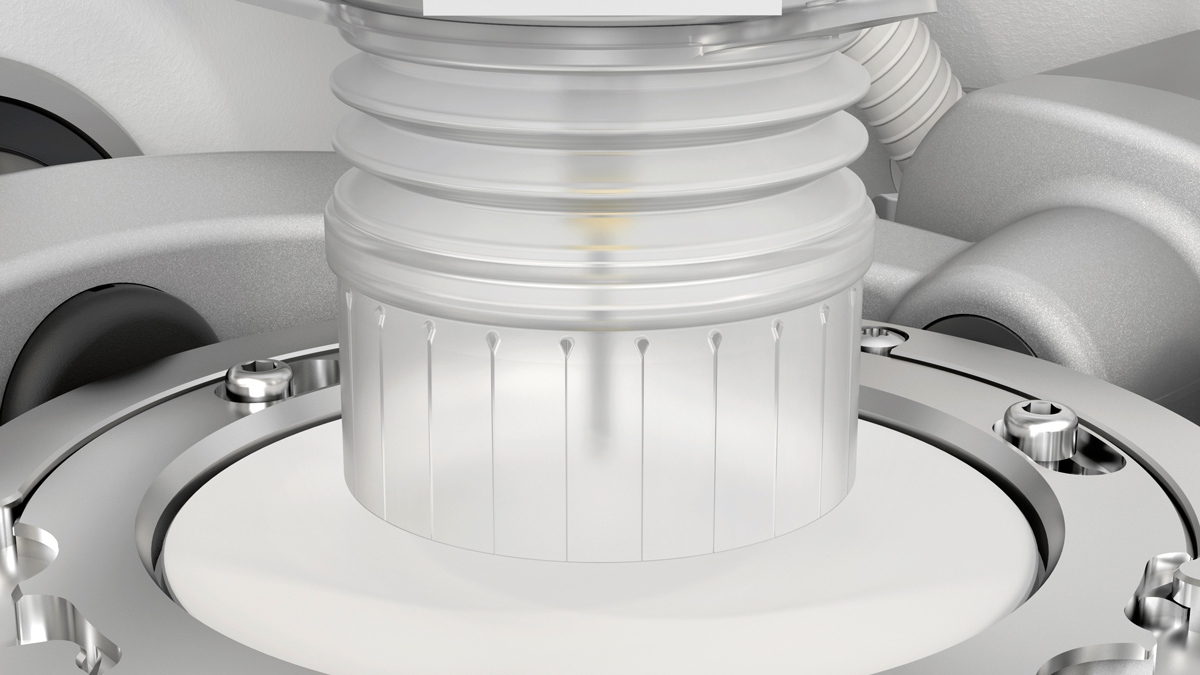

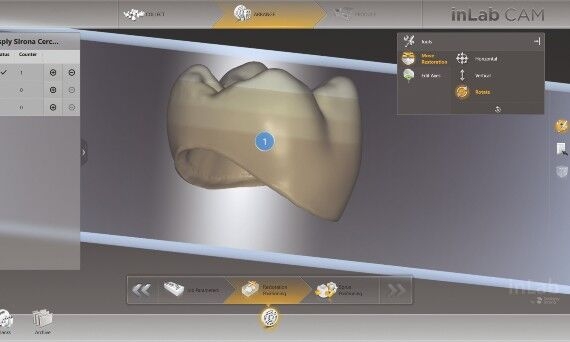

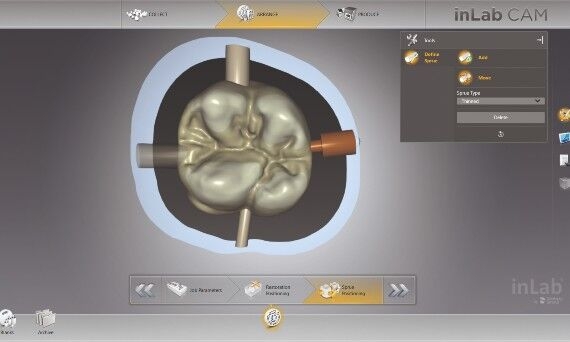

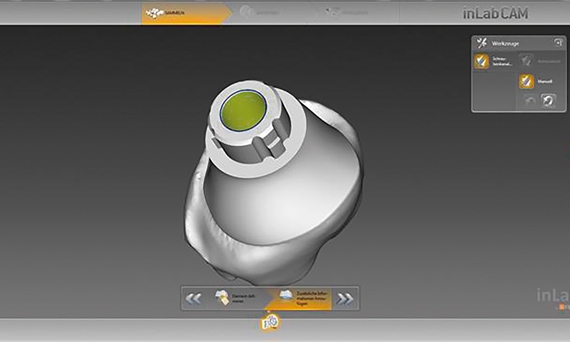

inLab MC X5 is a universal 5-axis production unit for wet and dry production of blocks and disks. It was designed to meet dental requirements in labs and focus on economic and effective production processes.

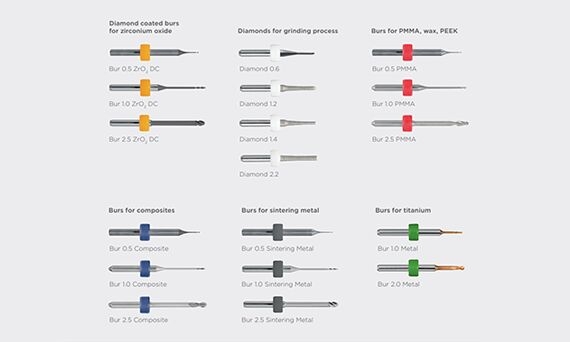

You benefit from a wide range of materials and can select from the high-quality materials of Dentsply Sirona and its CAD/CAM material partners for which the production processes of inLab MC X5 are optimized.