Contact Us

Find the best products for your lab.

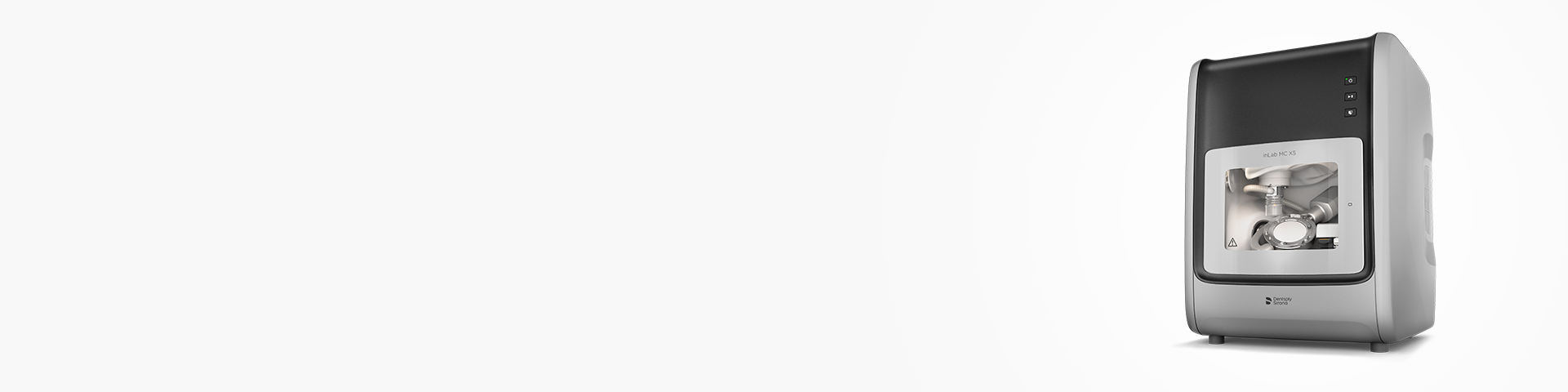

Reach out to learn more about what inLab MC X5 can do for you.

Efficient and flexible

inLab MC X5 is a universal 5-axis production unit for wet and dry production of blocks and disks. It was designed to meet dental requirements in labs and focus on economic and effective production processes.

You benefit from a wide range of materials and can select from the high-quality materials of Dentsply Sirona and its CAD/CAM material partners for which the production processes of inLab MC X5 are optimized.

Benefits

Why choose inLab MC X5?

Universal

The inLab MC X5 can be used for dry or wet production depending on the material and indication. More than thirty years of experience in the wet processing of glass ceramics make this the ultimate professional machine for the wet grinding of fully contoured restorations from final-strength monolithic materials. Alternating between wet and dry production, e.g., from glass ceramics to zirconia, is fast and easy.

Broad range of indications

The application range for inLab MC X5 enables dental labs to make productive use of their equipment. Processable disc height and setting angles offer flexibility for manufacturing implant restorations with heavily diverging screw channels or abnormally shaped stumps.

Open

It is the perfect complement to the inLab components inEos X5 and inLab software but can also be used to process other STL restoration data, including implant-supported restorations with screw access channels. Having its own CAM module, the unit can be connected flexibly to other CAD systems.

Wide range of indications

The application range for inLab MC X5 enables dental technicians to make productive use of their equipment. Processable disc height and setting angles offer flexibility for manufacturing implant restorations with heavily diverging screw channels or abnormally shaped stumps.

Features

Additional Products

inLab CAM Software

Smart positioning in the workpiece

For efficient material use and optimal preparation, the inLab CAM software positions the restoration in the workpiece according to your specifications. This takes previously positioned or prepared objects into account. Users can make adjustments without restrictions in the individual arrangement – for maximum flexibility and according to individual demands.

inLab Software 22: Integration of CEREC Primemill and seamless workflows

The inLab SW 22 CAD and CAM applications offer an extended connectivity to CEREC Primemill. The design and manufacturing workflow for CEREC Guide 3 surgical guide has been streamlined and the implant supported restoration design for DS PrimeTaper implant system is included. With the installation of inLab CAM SW 22.0, the new inLab CAM service is available. The database provides central management and storage of production data for Dentsply Sirona production units connected in the local network. This allows for an improved data that’s always up-to-date and higher security during data processing.

Product guarantee for inLab MC X5 milling unit

For every purchase of an inLab MC X5 milling unit Dentsply Sirona for a total period of 2 years. The statutory warranty rights are included in these conditions and remain fully applicable. Ask your dealer to register your new inLab MC X5 with us within the first 3 months after installation and receive up to 2 years warranty on your device free of charge.

Downloads

Please find below our most recent software downloads. Earlier versions are provided here.