© 2025 - Dentsply Sirona, All Rights Reserved

Contact Us

Find the best products for your lab.

Reach out to learn more about what inLab Profire can do for you.

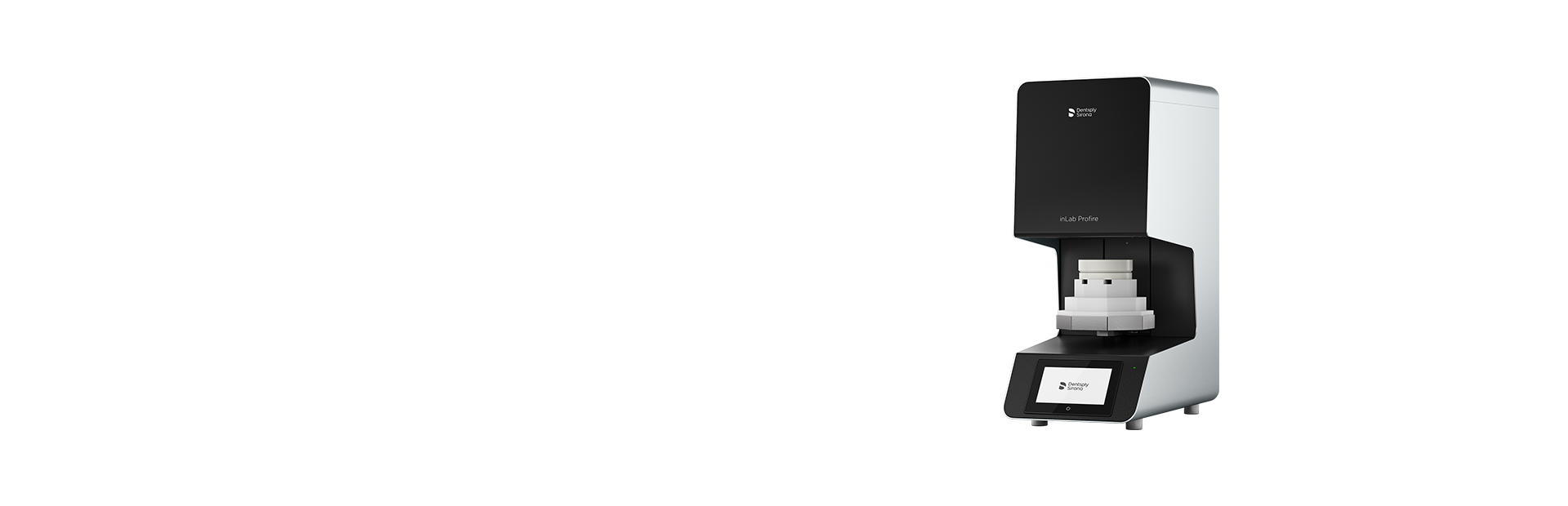

Powerful & comfortable

The inLab Profire sintering furnace combines proven process technology and convenient operation – for more process reliability and reproducible sintering results in the dental laboratory.

High-grade heating elements as well as homogeneous temperature distribution in the furnace chamber provide precise temperature control throughout the sintering process, for high quality sintering outcomes and reproducibility.

Benefits

Why choose inLab Profire?

Sintering of zirconium oxide and sinter metal¹ in just one furnace²

Conventional long-term sintering of zirconium oxide

Speed sintering for single restorations, frameworks and bridges

“Dry & Sinter” – Sintering with pre-drying

Simultaneous sintering of up to 60 units³ when stacking two sintering trays

Preprogrammed for validated sinter materials

Optional free programming

Sintering zirconium oxide and NPM — 2 in 1²

The inLab Profire can sinter zirconium oxide and non-precious metal in one furnace. For sintering non-precious metal1 with the product version inLab Profire with metal, only the sintering tray needs to be exchanged. Thanks to the integrated argon line, no further modifications are needed.

Downloads

Please find below the most recent Software and document versions. Further resources are provided within our Download Center.

Technical Data

Accessories

- Speed sintering tray, rack and fork for the sintering tray

- Zirconium oxide sintering beads

Options

- NPM sintering beads

- Sintering tray system for inCoris CC non-precious metal

- Argon gas management

Program types

- Speed

- Conventional sintering

- Pre-drying and sintering

- Service programmes

- Auto-start function

Dimensions (W x H x D): 360 x 780 x 534 mm

Weight: 64 kg

Supply voltage: 200–240 V

Mains frequency: 50/60 Hz

Nominal power: 3500 W

Maximum sintering temperature: 1,650°C

- For validated sinter metal only

- Optional with the inLab Profire Zirconia + Metal

- For zirconium oxide; depends on the size of restorations and sinter supports