© 2025 - Dentsply Sirona, All Rights Reserved

Contact Us

Together we can achieve more.

Reach out to learn more about what Dentsply Sirona can do for you.

The strongest all-ceramic dental restoration material on the market

With a wide range of indications, from single units to multi-unit bridges, zirconia is the strongest all-ceramic dental restoration material on the market.

Our digital materials are optimized to work within Dentsply Sirona scanning machines, milling machines and furnaces, but can be used as part of your existing digital workflow. See how Dentsply Sirona digital materials fit for you.

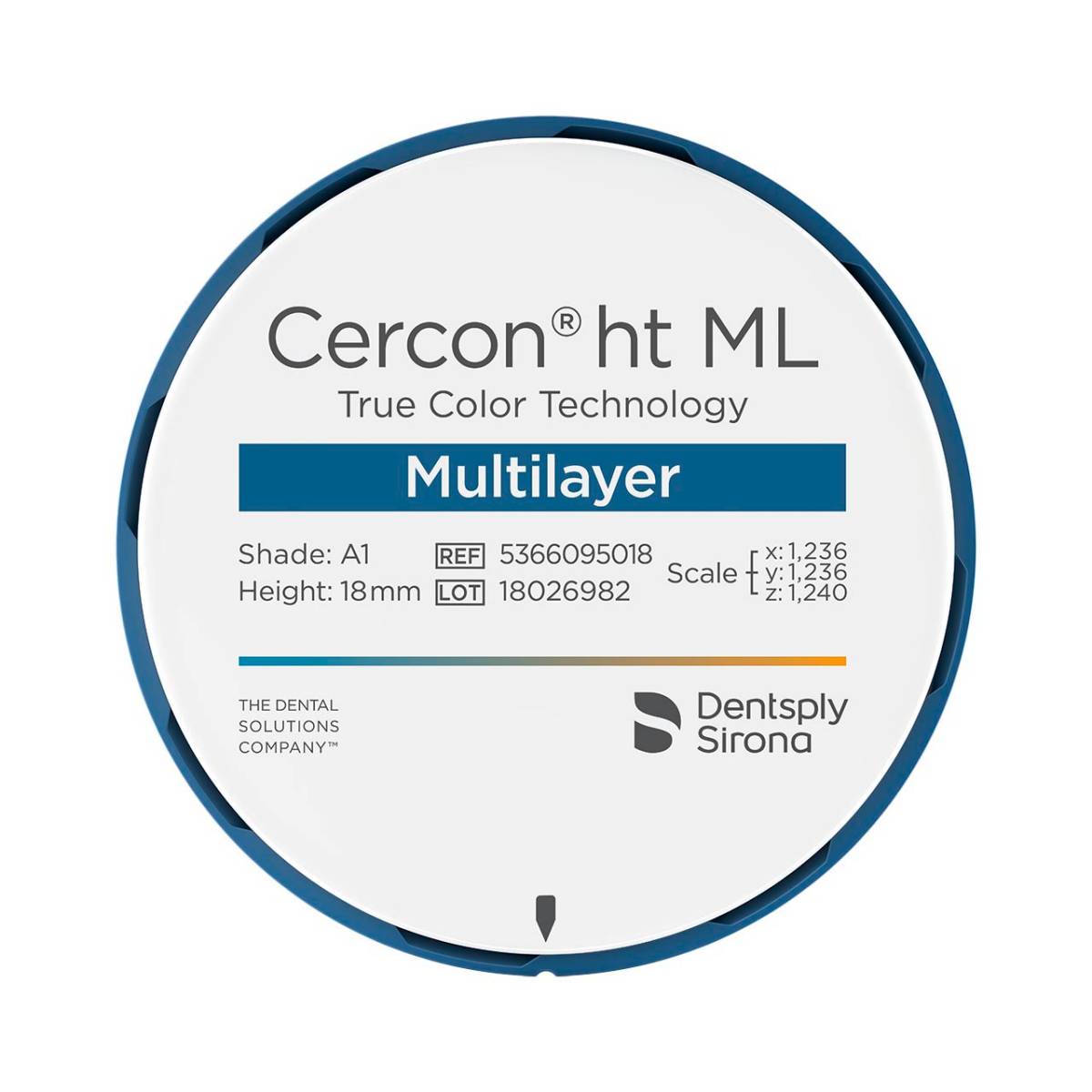

Zirconia materials

Benefits

Why choose Zirconia?

Time saving & efficiency

Identical sintering program and pre-sintered strength - Improves productivity with reproducible results and time savings ( no need to dip or veneer) - Achieve 16 shades from 6 basic shades using only 2-3 staining firing cycles - All 16 VITA shades are available.

True Color Technology

>20 years of zirconia experience - Expertise in ceramic materials - Our production process and in process control guarantee consistent quality from batch to batch - Shade results have been confirmed by customers in Europe and the USA

Reliable and high quality results

With over 70 clinical studies and international publications in 20 years, Cercon zirconium oxide is probably the best documented and evaluated zirconia ceramic material worldwide.

Easy Handling

New disc adapter fits a variety of milling machines - Compatible with many veneering systems - Conventional cementing can be used - Designed for open systems.

Digital materials in a seamless CAD/CAM Workflow