Learn more about the Dentsply Sirona Windows 11 Security Package to continue ensuring security and compatibility of your Dentsply Sirona devices.

Contact us

Find the products your practice needs to succeed.

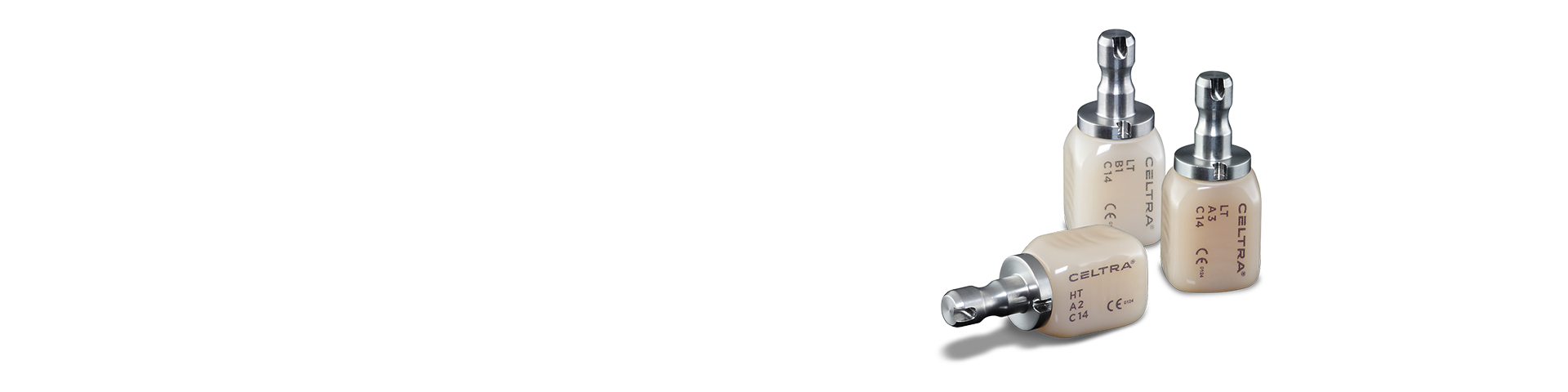

Bring innovation to your practice with Celtra Duo.

One highly esthetic block - two processing options

A proprietary Zirconia-reinforced Lithium Silicate (ZLS) microstructure makes Celtra Duo (ZLS) the one and only CEREC material that allows complete control over the workflow process without sacrificing the quality of the final restoration.

With crystallites four to eight times smaller than lithium disilicate blocks, Celtra Duo (ZLS) possesses an ultra-fine microstructure that combines high flexural strength with a high glass content, resulting in an impressive strength and beauty profile.

Benefits

Why choose Celtra Duo?

Flexible processing options

Choosing between mill and fire (370 MPa) or mill and polish (210 MPa) provides workflow flexibility and processing freedom with every case.

Chameleon effect for highly esthetic restorations

The high light conductivity and shade adaptation of Celtra Duo in conjunction with the remaining natural teeth and the pronounced opalescence create the desired chameleon effect.

Clinically proven strength for long-term clinical confidence

Even after 6,000 thermal cycles (41°F to 131°F) and 1.2 million chewing cycles with 70 Newtons of force, Celtra Duo demonstrated no loss in strength.

Automated sintering and glazing with CEREC SpeedFire

No programming of the furnace required.

Self-healing for greater strength and durability

The high glass content of Celtra Duo (ZLS) not only gives the material its excellent light-optical and mechanical properties, it also provides the added benefit of self-healing when fired.

During the firing cycle, as the glass transition temperature is reached, the glass ceramic turns into a highly viscous "liquid"; however, not viscous enough as to lose the shape of the restoration. Rather, the viscous glass fills any flaws caused by the milling process. After firing, having gone through the self-healing stage, as the material cools to room temperature, it hardens back to its original high strength.

"The first true high strength glass ceramic that offers the option to polish only or fire in the oven for additional strength...it's very unique in the market."

Dr. Bob Conte

"Celtra Duo covers a very broad spectrum of clinical indications. The advantage is we can work quickly, saves us time, makes us more efficient."

Dr. Andrew Hall

The science behind the block

Learn more about Celtra Duo (ZLS) and the recommended ways to handle the material in clinical application.

Preparing Celtra Duo (ZLS)

The preparation requirements of Celtra Duo (ZLS) are similar to other all-cermic restorations. Clinicians should aim for 1.5mm to 2mm of occlusal reduction with at least 1mm of axial reduction.

As with all CEREC restorations, the margins are the most critical part of the preparation and should be smooth and polished. Any milled restoration requires smooth polished margins so that the milling unit can adequately mill Celtra Duo (ZLS) restorations with ease.

Option 1: Mill and Fire

Characterization and firing technique

Fired restorations have a flexural strength of 370 MPa.

The induction furnace CEREC SpeedFire by Dentsply Sirona combines the processes of sintering and glazing in one compact, user-friendly device. The CEREC SpeedFire reaches a maximum heating rate of 300 °C per minute – no preheating or holding temperatures are necessary. Its induction technology ensures a perfectly homogeneous temperature distribution. Its dimensions make the CEREC SpeedFire a compact device that fits in any practice.

No firing schedules are required for CEREC SpeedFire. All sintering and glazing processes are completely automated: The CEREC Software sends the order with the necessary information to the furnace, eliminating the need for manual programming.

Option 2: Mill and Polish

Milled restorations have a flexural strength of 210MPa after polishing.

Downloads

Further downloads are provided within our Download Center.