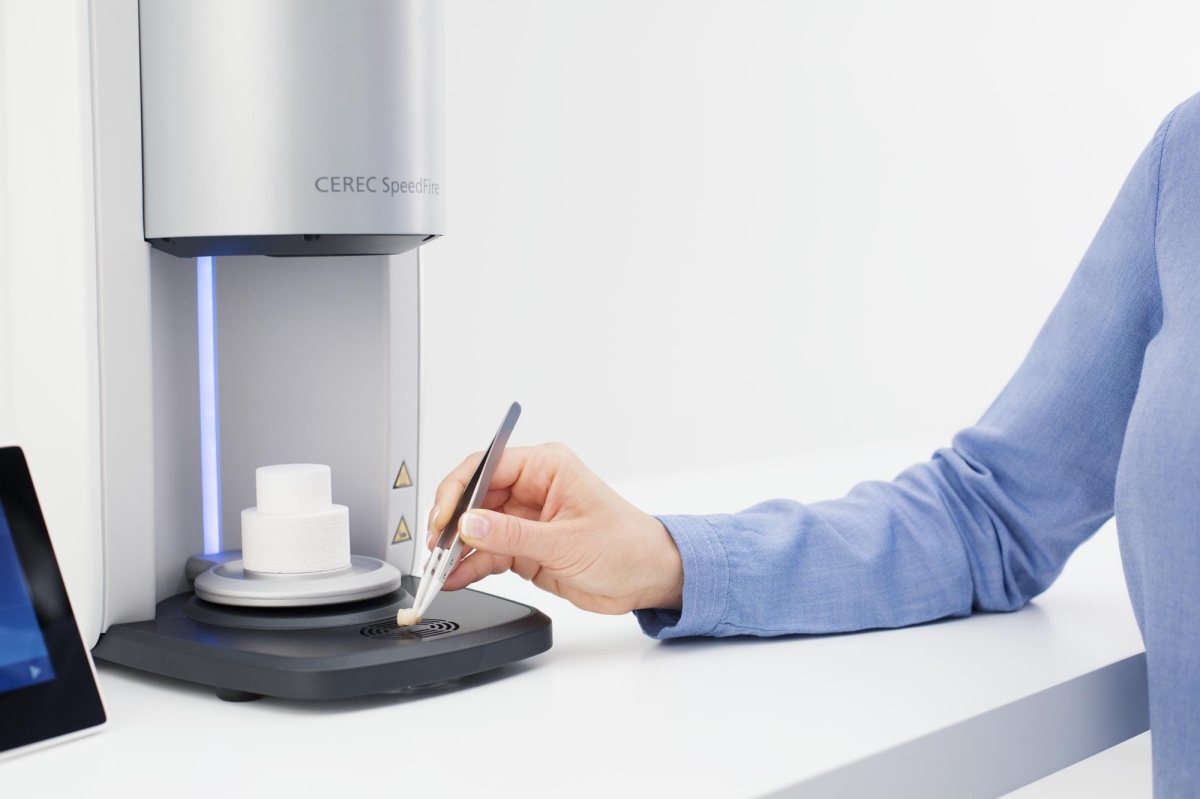

Full contour zirconia restorations in one session

CEREC SpeedFire is the smallest and fastest sintering furnace on the market and can typically sinter a crown in 10 to 15 minutes. The advantages of full-contour zirconia can thus also be used for chairside treatment. If required, a glaze can be applied with the CEREC SpeedGlaze that can be fired in just a few minutes in the CEREC SpeedFire. Besides CEREC Zirconia, CEREC SpeedFire can as well process partner materials, such as IPS e.max CAD (Ivoclar Vivadent) or Suprinity PC (VITA Zahnfabrik).