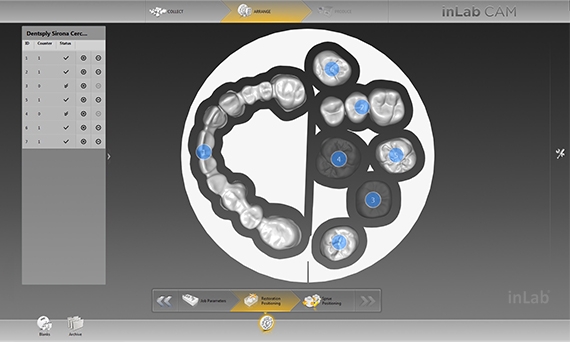

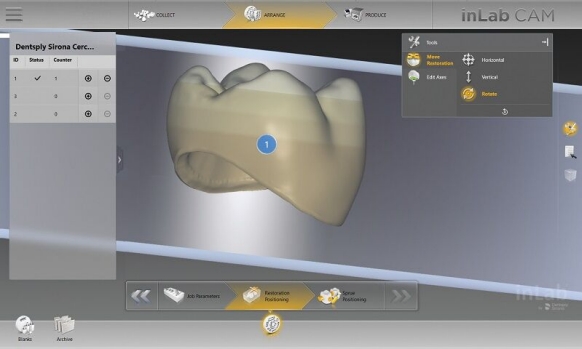

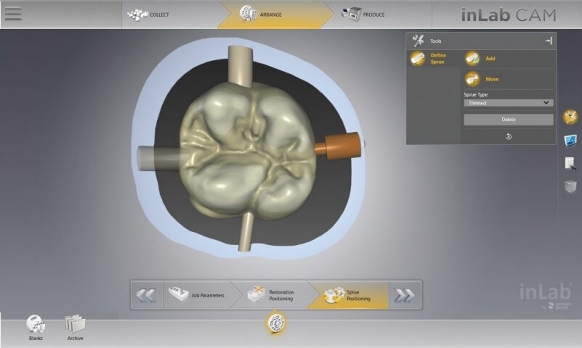

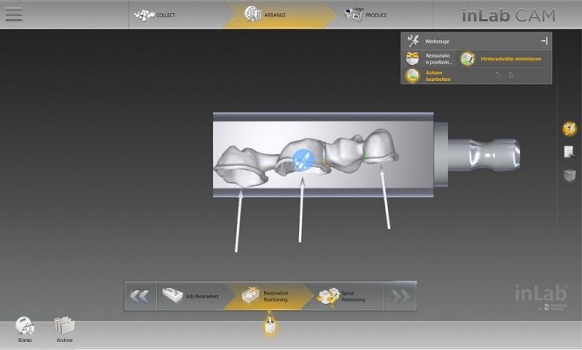

Software for efficient production processes

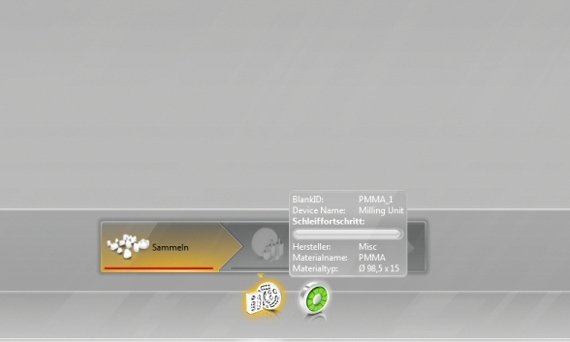

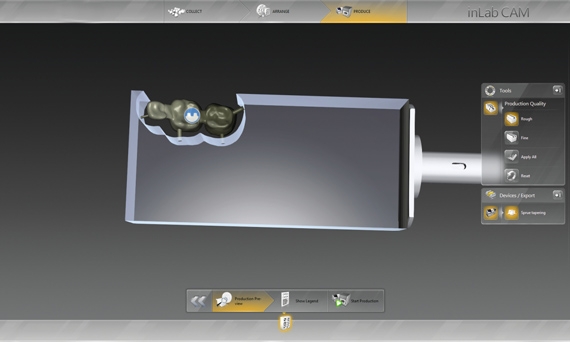

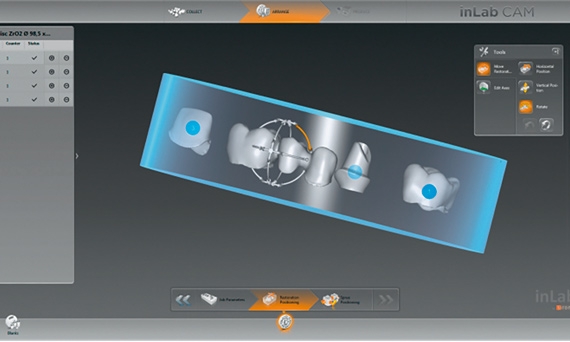

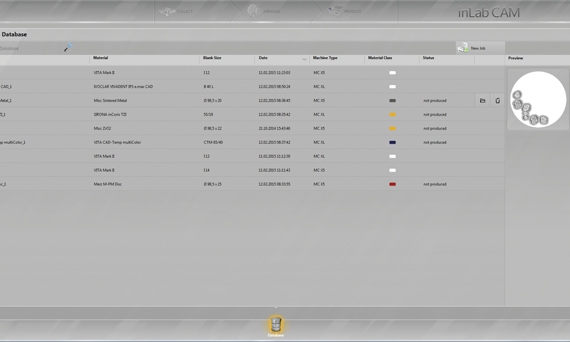

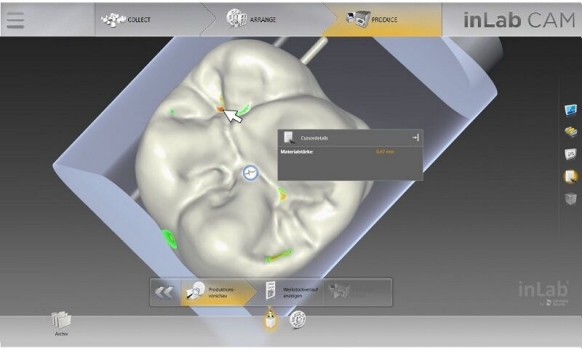

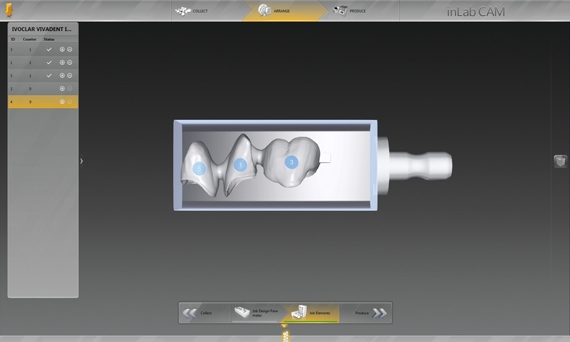

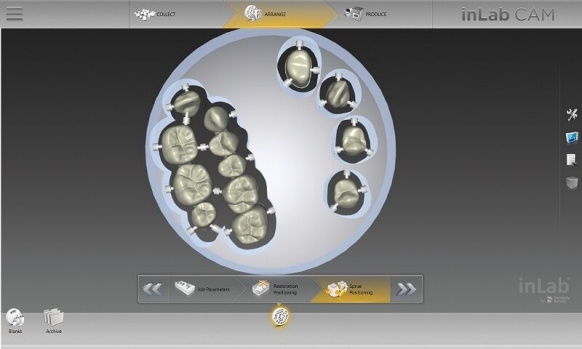

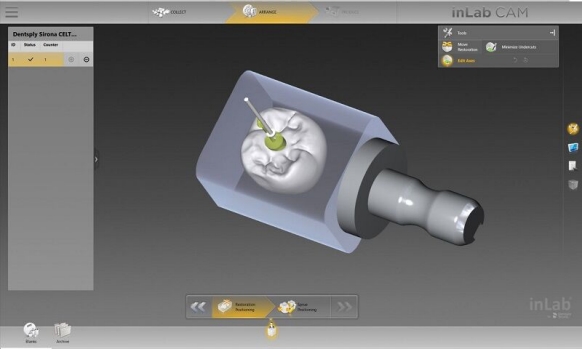

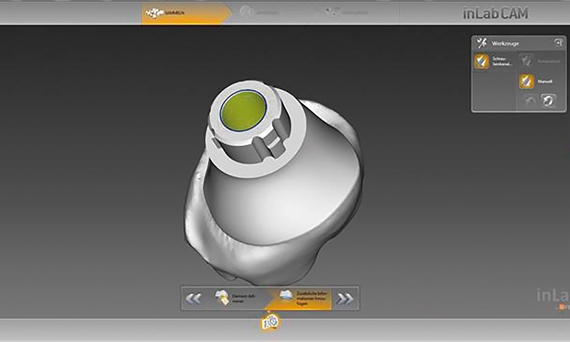

Two devices — one perfect workflow: The inLab CAM Software has been specially developed for the Dentsply Sirona inLab MC X5 and inLab MC XL milling units. All essential process steps, system configurations and integrated service functions can be carried out quickly and easily via the user-friendly interface. In addition, the software provides the quality management of a dental laboratory with a valuable documentation tool that stores all essential information on job history, workpieces produced, and materials used.